The Functionality of Pressure Regulators

The Functionality of Pressure Regulators

Gas pressure reducers are indispensable tools that ensure safety and efficiency across multiple industries. By controlling and stabilizing gas pressure, they protect equipment, optimize performance, and maintain safety standards. As technology advances, the design and functionality of these devices continue to evolve, making them even more effective and adaptable to the diverse needs of various applications. Understanding the importance and operation of gas pressure reducers is essential for professionals across fields who rely on gas systems in their operations.

The Rise of Superchargers Revolutionizing Electric Vehicle Charging

4. Versatility Available in various sizes and configurations, PRRs can be tailored to suit a wide range of applications and industries, making them a versatile component of fluid and gas control systems.

Types of Gas Heat Exchangers

Safety is a paramount consideration in the design and operation of PRS. These stations are equipped with multiple safety valves and monitoring systems that ensure any irregularities are swiftly addressed. Moreover, pressure relief valves are installed to prevent over-pressurization, which can lead to catastrophic failures.

Types of Relief Valves

Electric valves come with built-in position indicators that provide real-time feedback on the valve’s status, which is invaluable for monitoring and automation purposes. Many modern electric valves also include advanced features such as fail-safe modes, allowing them to default to a safe position in the event of a power failure.

1. Spring-Loaded Relief Valves These valves use a spring mechanism to hold the valve closed until the system pressure exceeds the setpoint. Upon reaching the setpoint, the valve opens, allowing pressure to release.

Furthermore, maintaining privacy and data security is paramount as regulators increasingly rely on big data analytics. Establishing robust frameworks to protect personal information while promoting transparency and accountability in the regulatory process is crucial. This requires ongoing dialogue between regulators, businesses, and the public to build trust and ensure that the data used is both ethical and secure.

Conclusion

At its core, a gas pressure regulator is a mechanical device that reduces the pressure of the incoming gas to a predetermined output pressure. This is particularly important because gases are often supplied at relatively high pressures, which can be dangerous if not managed properly. By regulating the pressure, the device helps prevent potential accidents, such as leaks or explosions, that can occur if the pressure is too high.

There are several types of gas-to-gas heat exchangers, including shell and tube heat exchangers, plate heat exchangers, and finned tube heat exchangers. Each type has its advantages and limitations depending on the specific requirements of the application. For example, shell and tube heat exchangers are commonly used in high-pressure and high-temperature applications due to their robust construction and ability to handle a wide range of operating conditions.

There are various types of gas meters, including diaphragm meters, rotary meters, and ultrasonic meters. Diaphragm meters are commonly used in residential applications due to their reliability and simplicity. Rotary meters, on the other hand, are suitable for larger commercial and industrial applications as they can handle a higher flow rate. Meanwhile, ultrasonic meters offer advanced capabilities, such as improved accuracy and easy integration with smart technologies.

The Organization of Natural Gas A Vital Energy Resource

The fundamental working principle of a pressure reducer is relatively straightforward. It consists of an inlet and an outlet, along with an adjustable spring mechanism. When high-pressure gas enters the reducer, it pushes against a diaphragm connected to the spring. The diaphragm moves, adjusting the size of the outlet opening, which controls the flow of gas exiting the reducer. If the output pressure rises above a set limit, the diaphragm moves to decrease the opening size, thus reducing the flow and maintaining a stable pressure.

For example, in the healthcare sector, NG technologies facilitate telemedicine and remote patient monitoring. With enhanced connectivity, doctors can diagnose and treat patients from a distance, making healthcare services more accessible, particularly in rural and underserved areas. Real-time data transmission allows for immediate analysis, improving patient outcomes and streamlining workflows. Moreover, as wearable technology becomes more integrated with NG networks, individuals can monitor their health metrics in real time, fostering a proactive approach to personal health.

Cyclone separators find their applications across numerous industries. In the food processing sector, they are used to remove contaminants from flour, sugar, and other powdered products, thus ensuring product purity and safety. In the pharmaceutical industry, they help maintain clean environments by controlling airborne particles.

For pressure regulators to function effectively, regular calibration and maintenance are critical. Over time, components can wear out, leading to inaccuracies in pressure regulation. Routine checks and adjustments can help to ensure that the device operates optimally, thereby prolonging its lifespan and maintaining system integrity.

To ensure that gas safety relief valves function effectively, regular maintenance is essential. Here are some best practices

Additionally, air purifiers are beneficial for those living in urban areas where traffic congestion and construction work contribute to higher pollution levels. With many people spending a significant amount of time indoors, particularly in small apartments or offices, the need for clean indoor air becomes paramount. An air purifier can act as a safeguard against the harmful effects of outdoor pollutions, such as particulate matter and volatile organic compounds (VOCs), creating a sanctuary of clean air within closed spaces.

Gas Filtration An Essential Process in Environmental Management

In today’s fast-paced industrial landscape, flexibility and efficiency are paramount. As businesses strive to optimize processes, skid mounted equipment has emerged as a versatile solution that enhances operational productivity across a broad spectrum of industries, including oil and gas, mining, pharmaceuticals, and construction.

4. Regulators with Built-in Safety Features Many modern GPRVs are equipped with safety features, such as excess flow shutoff and pressure relief mechanisms, to prevent over-pressurization and ensure safe operation.

In recent years, regulatory frameworks surrounding air quality and emissions have become increasingly stringent. Governments and international organizations are imposing stricter limits on permitted emissions, driving industries to adopt more advanced gas filtering technologies. Compliance with these regulations is not only essential for legal operations but also for maintaining a positive public image and meeting the expectations of environmentally conscious consumers.

Understanding the Equipment Mounted on a Slider

Applications of Pressure Regulating Valves

The Importance of Natural Gas in Modern Energy Solutions

- Safety By controlling gas pressure, regulators minimize the risk of leaks, explosions, and other hazardous situations. They help ensure that the gas is delivered at a safe level to appliances such as heaters, stoves, and industrial equipment.

2. Safety Relief Valves (SRVs) Similar to PRVs, SRVs are used for both liquids and gases. They provide a quick and effective method for controlling overpressure in a system.

Conclusion

In summary, pressure relief valves are indispensable components in safeguarding industrial operations against the dangers of overpressure. Their simple yet effective design allows them to play a crucial role in protecting both equipment and personnel. By understanding their importance, working principles, and maintenance requirements, industries can ensure safer and more efficient operations. Investing in the right pressure relief valve and maintaining it properly is not just a matter of compliance—it is a fundamental aspect of operational excellence.

Moisture and Dirt Barrier

In conclusion, balanced mechanical seals are a vital technology in modern industrial applications. Their ability to provide reliable sealing solutions under high pressure and harsh conditions makes them indispensable in many sectors. By understanding the principles of balanced mechanical seals and investing in proper installation and maintenance practices, industries can maximize the efficiency and lifespan of their equipment while minimizing environmental impact and operational costs. As technology advances, the development of even more efficient and robust seal designs will continue to enhance the capabilities of balanced mechanical seals in the ever-evolving landscape of industrial engineering.

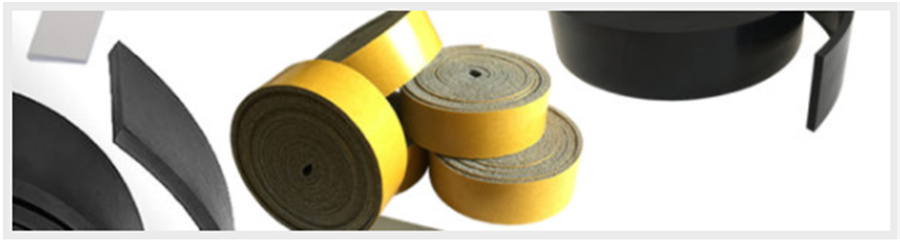

Thin rubber strips typically range from a few millimeters to several centimeters in width and can be made from various types of rubber, including natural rubber, synthetic rubber (like neoprene, EPDM, and silicone), and other elastomers. Their thin profile allows for easy manipulation, making them suitable for applications where space is limited. The flexibility of these strips enables them to bend and conform to different shapes, which is particularly useful in sealing and insulating applications.

1. Water Leaks If you notice water pooling inside your car after rain or washing, this is a strong indication that your door seal may be compromised.

2. Choose Your Material Adhesive weather stripping comes in various materials, including foam, rubber, and vinyl. Each has its advantages, so choose one that best suits your needs and climate.

In conclusion, door foam strips offer an effective and affordable solution for enhancing a home's insulation. With their ability to reduce energy costs, improve indoor comfort, and enhance air quality, they are a valuable addition to any home improvement project. As homeowners continue to seek ways to create energy-efficient spaces, the installation of door foam strips will undoubtedly play a crucial role in achieving a more sustainable and comfortable living environment. Whether you are building a new home or simply looking to upgrade your current living situation, consider adding door foam strips to your list of priorities. The benefits they provide can lead to long-term savings and greater enjoyment of your living spaces.

4. Insulation Properties The closed-cell structure not only provides cushioning but also acts as an insulator. This makes it effective for soundproofing and thermal insulation, enhancing energy efficiency in buildings and vehicles.

Regular maintenance and timely replacement of mechanical seals are essential for the efficient operation of centrifugal pumps. Understanding the signs of wear and following a systematic replacement procedure can lead to significant savings in operational costs and downtime. By ensuring that the mechanical seals are in good condition, pump operators can maintain the integrity of their systems and maximize the lifespan of their equipment.

The Importance of Foam Weather Seals in Home Efficiency

Conclusion

Key Properties and Benefits

These seals are designed to function effectively even under fluctuating pressures and temperatures. Their ability to handle high pressures reduces the risk of leaks, which can be dangerous and costly. In environments where toxic or flammable fluids are present, a failure in the seal can lead to catastrophic results, including environmental damage, safety hazards, and significant financial losses.

Materials Used in Seal Strips

In the realm of construction, home improvement, and DIY projects, the need for reliable adhesive solutions is paramount. One such solution that has gained traction in recent years is black foam tape, specifically the single-sided variety. This tape is not only effective but also versatile, making it a favorite among both professionals and hobbyists.

This type locks onto the doorframe, creating a robust barrier against drafts This type locks onto the doorframe, creating a robust barrier against drafts

This type locks onto the doorframe, creating a robust barrier against drafts This type locks onto the doorframe, creating a robust barrier against drafts exterior door weatherstripping types. Although installation requires precision and may involve some modifications to the doorframe, its durability makes it a long-lasting choice for areas with substantial environmental extremes.

exterior door weatherstripping types. Although installation requires precision and may involve some modifications to the doorframe, its durability makes it a long-lasting choice for areas with substantial environmental extremes.Aesthetic Enhancement

1. Compatibility Ensure that EPDM is suited for the chemicals and conditions it will encounter in its application.

5. Install the New Weather Stripping Start at one end of the door and press the new weather stripping into place. If the material requires adhesive, apply it according to the manufacturer’s instructions.

- Electronics The seals are also used in electronic devices, where moisture resistance is vital to ensure the longevity of components.

The adhesive side of the tape is coated with a high-performance adhesive, which ensures strong bonding capabilities. Depending on the intended use, the adhesive can be formulated for permanent or temporary adhesion. Moreover, the tape is typically resistant to moisture, chemicals, and temperature fluctuations, adding to its performance characteristics.

Depending on the severity of the damage, you may choose one of the following methods

2) Check whether the product has vulcanization defects;

- Home Improvement They can be used for sealing cracks and gaps in doors and windows, preventing drafts and enhancing energy efficiency.

Types of Weather Stripping

- Double Mechanical Seals Used in more demanding applications, double seals provide an additional layer of protection. They have two seal faces and are often used when a higher level of security against leakage is required. The second seal acts as a backup, ensuring that if one seal fails, the other can still contain the fluid.

The core component of adhesive rubber foam tape is typically made from closed-cell rubber or neoprene foam, which provides excellent cushioning and insulation. The adhesive backing, usually made from acrylic or rubber-based adhesive, ensures strong adhesion to various surfaces, including metals, plastics, and wood. The foam structure not only adds to the toughness of the tape but also allows it to compress and conform to irregular surfaces. This feature is particularly beneficial when used in applications where a tight seal is necessary to prevent air, dust, and moisture from penetrating.

Door strips are protective materials that are applied to the edges of car doors. They can be made from various materials, including rubber, vinyl, and plastic. The primary purpose of door strips is to prevent damage from various external factors. Whether it’s an accidental bump against a wall or another car, or the wear and tear from daily use, door strips act as a buffer that minimizes dents and scratches.

4. Power Generation Mechanical seals are used in turbines and generators to ensure the efficient operation of power plants. The robust design of a 1.375% mechanical seal can significantly enhance the performance and lifespan of equipment.

The Importance of Trunk Weather Stripping

Car door window strips, though often overlooked, are essential to the overall functionality and comfort of your vehicle. By understanding their importance and maintaining them properly, you can ensure a safer, quieter, and more enjoyable driving experience. Regular inspection and timely replacement of worn-out strips can save you from potential costly repairs and enhance the longevity of your vehicle’s interior. So the next time you perform a maintenance check, don’t forget to give those window strips some attention!

In conclusion, foam weather seals play a crucial role in improving the energy efficiency of homes. They not only enhance indoor comfort but also lead to significant savings on energy bills while contributing positively to environmental sustainability. With their ease of installation and long lifespan, foam weather seals are an excellent option for homeowners looking to take control of their energy consumption. Investing in these simple yet effective solutions can result in a more comfortable, efficient, and eco-friendly home.

Conclusion

Maintaining your weather stripping is essential for its longevity. Regularly inspect it for wear and tear and replace it as necessary to ensure continued efficiency.

5. Install the Weather Stripping Depending on the type, peel off the backing or use nails/screws as required, and press the weather stripping into place.

Interior door seals are typically made from materials such as rubber, foam, or weatherstripping, designed to provide a tight fit between the door and its frame. Their primary function is to prevent air leakage, which can lead to drafts and temperature imbalances throughout a building. By ensuring a proper seal, homeowners can maintain a consistent indoor temperature, reduce reliance on heating and cooling systems, and ultimately save on energy bills.

Types of Door Seal Adhesives

Once the seal is in place, close the door and listen for any wind or noise that suggests the seal may not be tight. You can also perform a water test by lightly spraying water over the door and observing the interior for any leaks.

When it comes to home insulation and energy efficiency, small details can make a significant difference. One such component that often gets overlooked is weather stripping. Among the various options available, 1% thick foam weather stripping has gained recognition for its effectiveness and versatility. This article delves into what 1% thick foam weather stripping is, its benefits, and how to install it in your home.

Applications of EPDM Foam Rubber Seals

A mechanical seal is a device used to prevent the leakage of fluids within a mechanized system. Unlike traditional packing methods, which can wear and degrade over time, mechanical seals provide a more reliable solution for isolating fluids. They consist of two primary components a rotating face and a stationary face, which come into contact to create a sealing barrier. This contact is often enhanced by various materials and designs to withstand the specific pressures and temperatures of the application.